3devo Filament Makers

Τα 3DEVO Filament Extruders αποτελούν μια εξαιρετική all-in-one λύση για μικροπαραγωγή πειραματικών/ερευνητικών αναλωσίμων για 3D printers. Διαθέτουν ενσωματωμένο filament winder, έλεγχο ροής και διατομής και ανάλογα το μοντέλο έχουν μεγάλο εύρος θερμοκρασίας και μείκτη για τα πρόσθετα.

Filament Makers

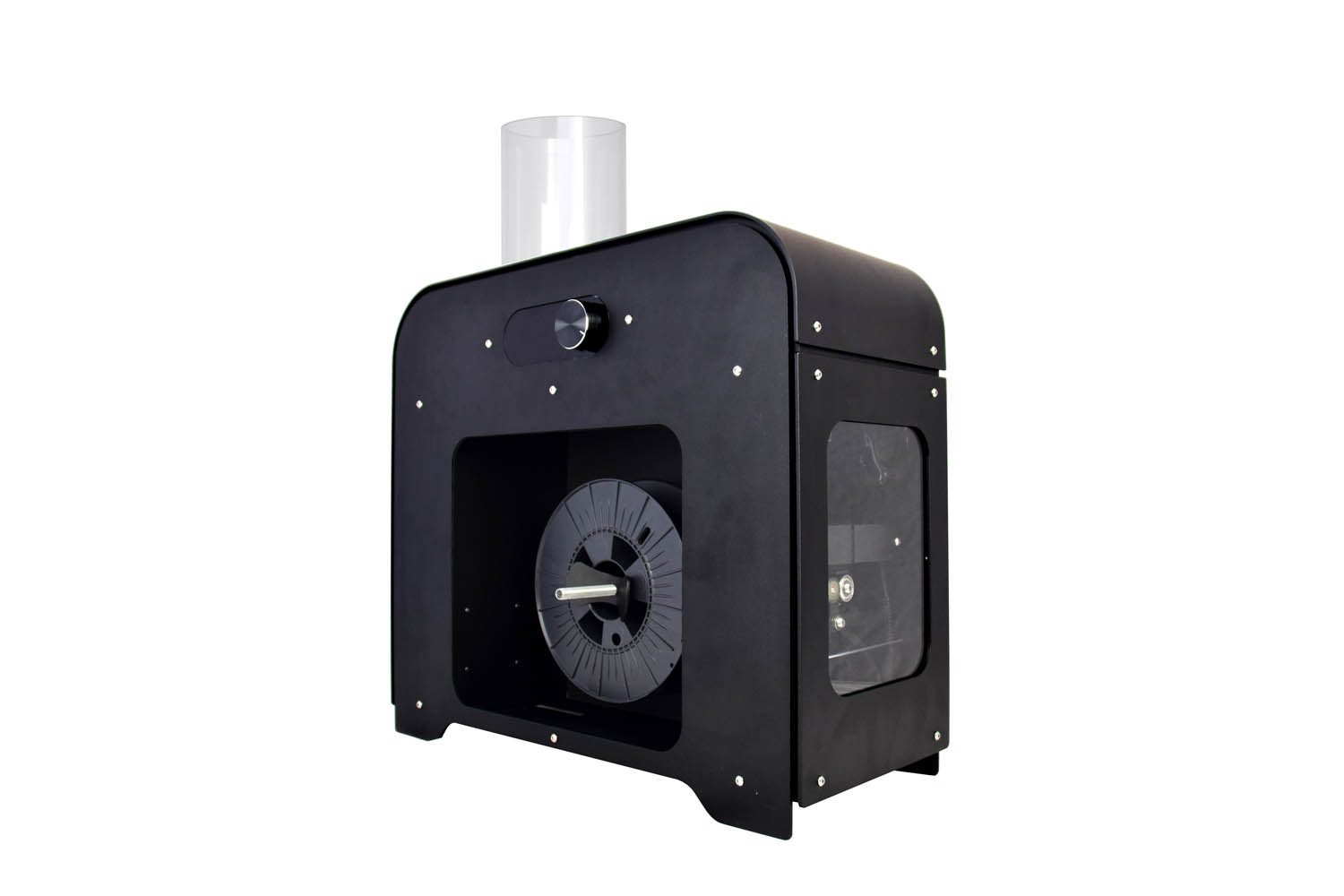

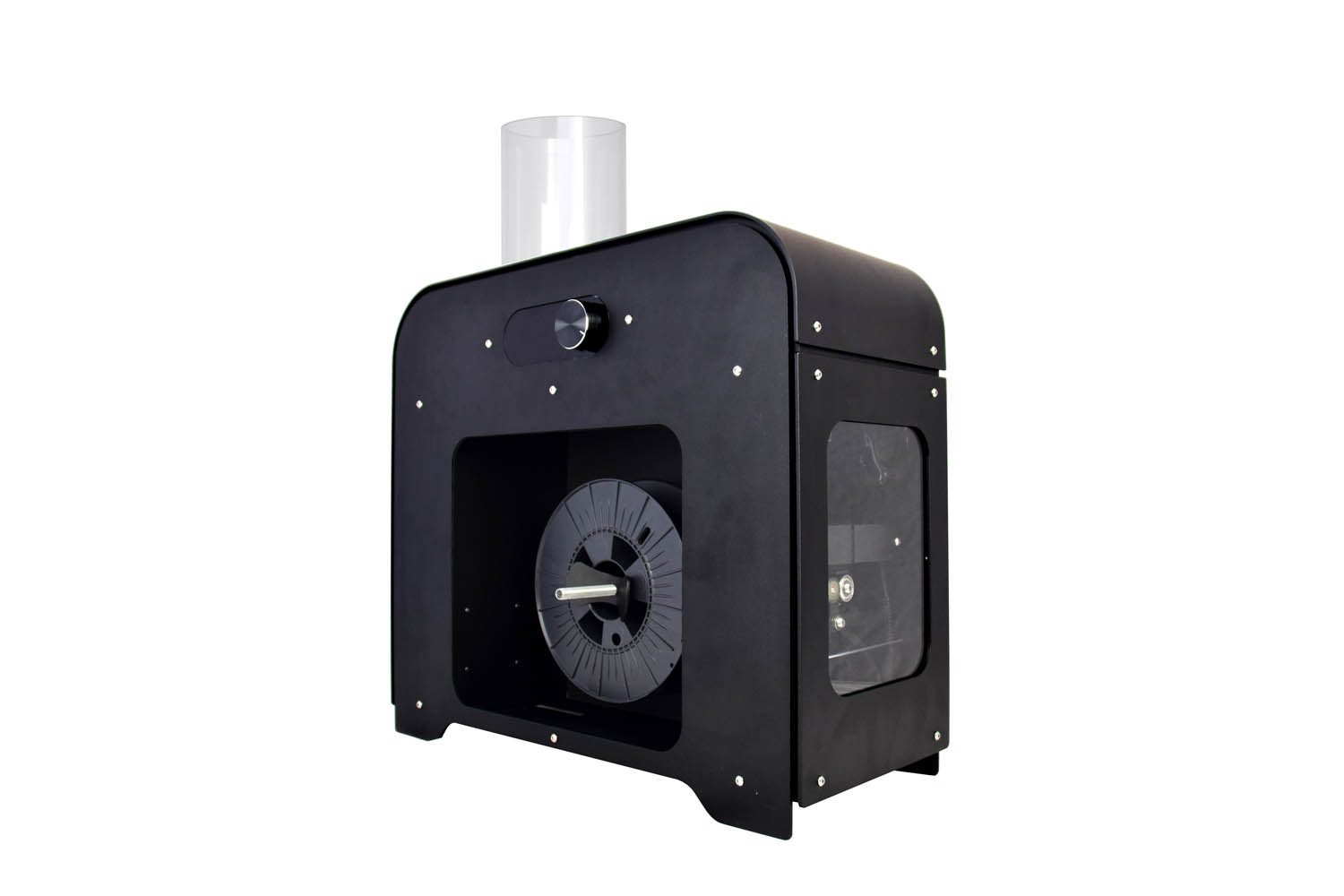

The Composer and Precision Series

The Composer and Precision Series filament makers are specialized, result-oriented machines with industrial quality power. Making polymers simpler than ever to work with, while offering even more possibilities in manufacturing and innovation.

Make filament out of pellets or shredded plastic regrinds right from your desk.

Temperatures

Temperatures

Extruder Screw

Extruder Screw

Materials Mixing

Diameter Range

Diameter Range

Heating System

Heating System

Connect

A Complete Filament Production Line.

Packed into one machine.

Control Panel

Display Interface

- Easily accessible settings

- Convenient standard material pre-sets

- Customizable material profiles for perfect results

Connectivity

- Simple USB connectivity with your computer/laptop

- Regular firmware updates and instant access to new features

Hopper

- Optical sensor to check the material level

- Removable tube; multiple sizes supported

- Built-in safety grille

Extruder

- 4 heating zones, reaching temperatures up to 450°C

- Nitride hardened steel extruder screw

- Swappable extruder design

- Optional mixing section (Composer Series)

- Replaceable extruder nozzle

Cooling System

- Dual fan system for even air distribution

- Adjustable fan angles for optimal air flow

- Customizable, material-specific fan speeds

Sensor + Puller System

Optical sensor

- Accurate diameter measurement between 0.5mm and 3.0mm; 43 micron precision

- One nozzle for all filament diameters

- Ideal sensor placement to ensure filament roundness

Puller system

- Automatic speed adjustment for accurate diameter control

- Changeable puller wheels to suit material temperature variations

Positioner

Set your own spool sizes, and with auto spooling let the system to the work. The filament maker will neatly position itself to get a nice-looking spool that won’t tangle.

Features

- Adjustable positioner, with a max spool width of 120mm

- Automatic spooling to user-defined size

- Retractable arm for neat, even winding of all spool sizes

Spool Winder

- Fit spools with a max Diameter: of 240mm, And a max width of: 120mm

- User-friendly slipper clutch for spool tension adjustments

- Swappable spool mount for quick changing between spools

Durable and Versatile Components

Hardened for Durability

The extruder screw in the Composer is machined for mixing. Its nitride-hardened interior ensures industrial-grade filament extrusion.

Extruder Mixing Zone

Enables you to blend different additives, plastics, fibers or powders

to create custom filaments.

Easy, Accessible and Automated

The unique vertical extrusion setup in the filament makers ensures precise roundness and accurately guides the filament to the spool.

A dual air cooling system, with adjustable fan speeds and positions, ensures optimal cooling settings for the materials you work with.

A sophisticated optical sensor and a dynamic puller system work together to achieve a diameter precision tolerance of +/- 0.05mm*.

*(to get the exact diameter tolerance tuning might be needed depending on material type)

User-friendly and easy to control.

An embedded OLED display and a single rotate-and-push control button provide easy access to all features and functionalities of the filament makers.

Connect your filament maker to your computer via USB to receive the latest firmware and feature .

Unlimited filament, neatly spooled

Thanks to its swappable spool mount, the filament makers support diverse spool sizes and quick spool changes.

Set your custom spool dimensions to get a neatly rolled spool of filament.

Adjust the built-in slipper clutch to get the right amount of tension in your filament spool.

Building 3D printing materials with our filament makers

Material Pre-Sets

Custom Materials

Software Updates

Compounding

Homogenous Blends

Custom Colors

Compare Filament Makers

At a glance

Composer Series 350 / 450 |

Precision Series 350 / 450 |

|

| Color | Silver powder coated aluminum | Black powder coated aluminum |

| Temperature Peek Point | 350°C (Composer 350) / 450°C (Composer 450) | 350°C (Precision 350) / 450°C (Precision 450) |

| Heating Zones | 4 – Independent Controllable | 4 – Independent Controllable |

| 4 Controllable heating Zones | Yes | Yes |

| Mixing Screw | Material mixing screw | High-flow screw |

| USB Connectivity | Yes | Yes |

| Firmware Updates | Free | Free |

| Extrusion Data Analysis | Real-time | Real-time |

Compare Filament Makers

Materials

Composer Series 350 / 450 |

Precision Series 350 / 450 |

|

| Presets – Standard Materials | PLA, ABS, PS, PC | PLA, ABS, PS, PC |

| Standard Material Tested | PETG, TPU, TPE, PPS, PVA, Bio PE, NEW PET and PA (6,12,66) | PETG, TPU, TPE, PPS, PVA, Bio PE, NEW PET and PA (6,12,66) |

| Material Mixing Screw | For advanced compounding | For superior speed |

|---|---|---|

| Presets – Professional Materials | PEEK (450 Series Only) | PEEK (450 Series Only) |

| Professional Materials Tested | PEKK, PAEK, PEI, PSU, PES (450 Series Only) | PEKK, PAEK, PEI, PSU, PES (450 Series Only) |

| Material Updates | Presets added regularly – New materials tested frequently (450 Series Only) | Presets added regularly – New materials tested frequently (450 Series Only) |

Compare Filament Makers

Performance

Composer Series 350 / 450 |

Precision Series 350 / 450 |

|

| RPM Range | 2 – 15 rpm | 2 – 15 rpm |

| Filament Diameter Range | 0.5 – 3 mm (0.02 – 0.12 inches) | 0.5 – 3 mm (0.02 – 0.12 inches) |

| Optical Sensor Accuracy | 43 microns (1.69 mils) | 43 microns (1.69 mils) |

|---|---|---|

| Nozzle Extruder | Diameter 4 mm (0.16 inches) Replaceable |

Diameter 4 mm (0.16 inches) Replaceable |

Compare Filament Makers

Dimensions & Power

Composer Series 350 / 450 |

Precision Series 350 / 450 |

|

| Height | 506 mm (19.2 inches) | 506 mm (19.2 inches) |

| Width | 448 mm (17.6 inches) | 448 mm (17.6 inches) |

| Depth | 216 mm (8.5 inches) | 216 mm (8.5 inches) |

| Hopper Volume | 2 liters | 2 liters |

| Net Weight | 24.5 kg (54 pounds) | 24.5 kg (54 pounds) |

| Gross Weight | 27 kg (59.5 pounds) | 27 kg (59.5 pounds) |

| Consumption (Avg.) | 300 – 400 W | 300 – 400 W |

| Consumption Max. | 1300 W | 1300 W |

| Voltage | 110 – 230 V | 110 – 230 V |

| Hertz | 50 – 60 Hz | 50 – 60 Hz |

| Screw / Barrel Alloy | High chromium and molybdenum steel alloy -Nitrided – 3 stage Compression | High chromium and molybdenum steel alloy -Nitrided – 3 stage Compression |

Related Products

ReDeTec ProtoCycler+ w. grinder V3

6.399,00€ ME ΦΠΑFelfil Plastic Shredder+

1.790,00€ – 2.190,00€ ME ΦΠΑFelfil Spooler+

1.150,00€ ME ΦΠΑFelfil Evo Filament Extruder

1.120,00€ – 1.240,00€ ME ΦΠΑ