Raise3D Hyper Speed ABS

44,90€ ME ΦΠΑ

Hyper Speed ABS Filament is one of the specially developed filaments from the High-speed filament line for FFF printing. When printing at high speeds, the filament is rapidly fed into the heat block, and the polymer has very little time to melt, from solid to a molten state, which can cause nozzle clogging and poor bonding quality between layers. Additionally, ABS can be subject to warpage and delamination of the printed part during high-speed printing without a heated chamber.

With optimized molecular weight and stiffness, Raise3D Hyper Speed ABS is capable of achieving faster melting and cooling during high-speed printing, which results in lower temperature gradient and inner-stress of printed part. With almost no warpage and improved interlayer bonding, Hyper Speed ABS is also perfectly suitable for many functional prototyping parts, tools and fittings with many different possibilities for post-processing.

Comes in – 1.75mm – 1 kg spools

The Raise3D Hyper Speed ABS is a specially designed ABS (acrylonitrile butadiene styrene) filament from the Raise3D Hyper Speed filament lineup. Hyper Speed filaments are a part of a whole ecosystem created by Raise3D for high-speed 3D printing, called HyperFFF and also including hardware and software upgrades.

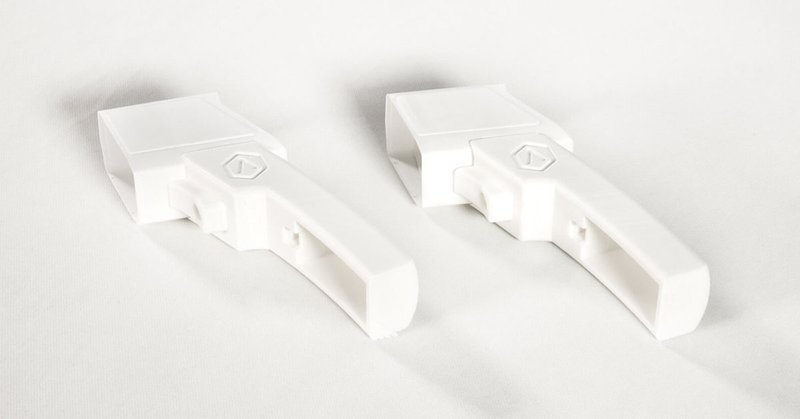

After installing and calibrating the new high-speed dual extruder and updating firmware and software, the printer’s speed can be increased up to 300 mm/s. At such speeds most conventional thermoplastics may cause nozzle clogging and show poor interlayer adhesion, since the filament has too little time to melt completely, being rapidly fed through the hotend. The optimized molecular weight for higher flowability and lower heat capacity of Hyper Speed filaments ensures rapid material melting and cooling, making for consistent extrusion and improved interlayer bonding. Such common ABS-printing issues as model warpage and delamination are also greatly reduced due to the improved properties of the new filament. Consistently high print quality and extremely fast printing speed allow for a wide application range of the Raise3D Hyper Speed ABS filament, including functional prototyping and design verification, jigs and fixtures manufacturing, and more.

The Raise3D PVA+ can be used as a support material for the Hyper Speed ABS. To ensure better first layer adhesion and prevent warpage, adding a brim or raft is recommended by the manufacturer. The Raise3D ideaMaker software provides printing profiles for Hyper Speed filaments, compatible with the Pro3 series machines.

Recommended printing parameters:

- Nozzle temperature: 210–260 °C

- Bed temperature: 55–65 °C

- Layer height: 0.1–0.2 mm

- Printing speed: 25–300 mm/s

- Cooling fan: on

- Drying temperature: 50 °C

Specifications

- Density (ISO 1183, GB/T 1033): 1.08 g/cm³

- Melt flow index (ISO 1133, 220 °C, 10 kg): 55 g/10 min

- Heat distortion temperature: 73 °C

- Water absorption (ISO 62: Method 1): 0.36%

- Tensile strength, X-Y (ISO 527): 45 ± 9 MPa

- Young’s modulus, X-Y (ISO 527): 1770 ± 165 MPa

- Elongation at break, X-Y (ISO 527): 40 ± 3%

- Bending modulus, X-Y (ISO 178): 1950 ± 165 MPa

- Bending strength, X-Y (ISO 178): 52 ± 7 MPa

- Impact strength, X-Y (ISO 180): 7.0 ± 1.0 kJ/m²

Spool specs

- Filament diameter: 1.75 mm

- Filament weight: 1 kg

- Available colors: White

- Color attribute: Solid

The Raise3D Hyper Speed ABS 1.75 mm filament is sold in 1 kg spools. It comes vacuum-sealed with desiccant.

Επιπλέον πληροφορίες

| Βάρος | Μ/Δ |

|---|---|

| Filament Type | |

| Technology | |

| Filament Brand | |

| Επιλογή Χρώματος | Natural, Black V2 |