Laser Aided Profiler

Το Laser Aided Profiler είναι μια συσκευή για αρχαιολογική χρήση, κατάλληλη για εύκολη και γρήγορη αποτύπωση των προφίλ αγγείων και άλλων ευρημάτων! Διαθέτει 2 Laser για αμφίδρομη σάρωση μέσω 2 καμερών που παρέχουν το προφίλ του ευρήματος στο λογισμικό σε πραγματικό χρόνο. Παρέχει διαστατικές πληροφορίες, εργαλεία αρχειοθέτησης για δημιουργία βιβλιοθήκης των μοντέλων, μαζί με έγχρωμη φωτογραφία τους για καλύτερη αναγνώριση. Έρχεται σε βολική βαλίτσα μεταφοράς για εύκολη μεταφορά στο πεδίο.

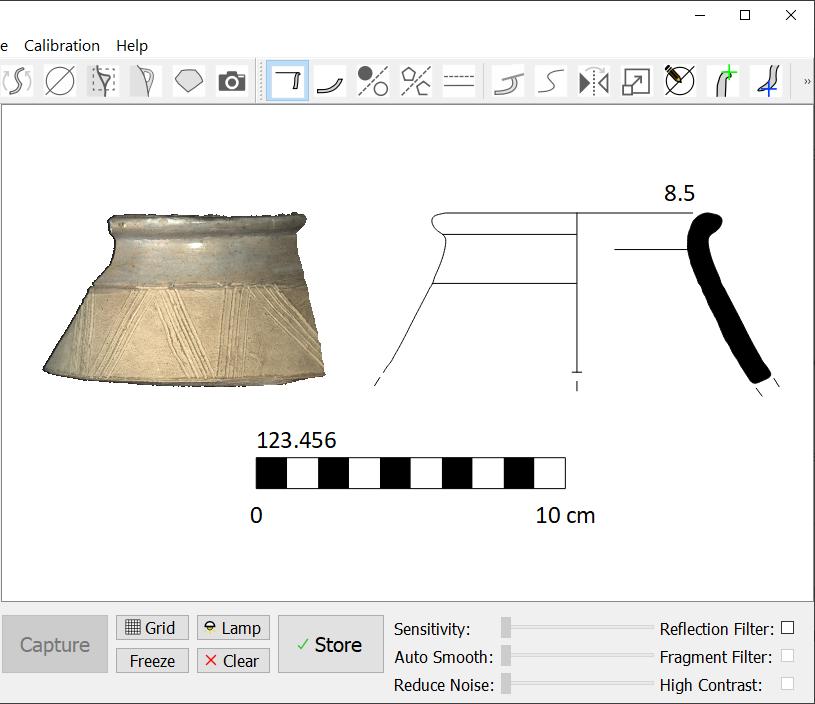

Laser Aided Profiler Precision pottery drawings made fast

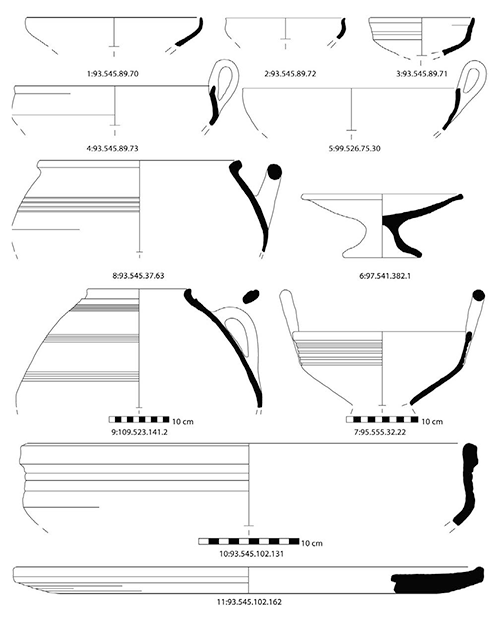

For busy archaeologists struggling with processing of large find assemblages, the Laser Aided Profiler device employs the latest technology for high-quality, rapid, digital documentation of ceramic fragments. Forget about the tedious drawing task and take your research to the next level.

Efficient

- Streamlined software application optimized for pottery fragment drawings

- 20 drawings per hour on average

- Digitized data immediately available for database storage, publishing, or further analysis

Laser Aided Profiler Robust and reliable

- Use it in the lab as well as in the field

- Withstands dusty environments and temperatures over 40 degrees Celsius

- Purely optical data acquisition, no moving parts

- Works even with strong ambient sunlight

- Eye-safe class 1 laser

Portable

- Comes with a handy suitcase

- Dimensions 46 x 34 x 15 cm (18 x 13 x 6 inches) for easy airplane transport

- Weight under 7 kg (15 lb.)

- Assembled and ready to work in 10 minutes

Use cases

- Digitize existing deposits to safeguard their contents and enable new research opportunities

- Process finds on the fly at the excavation sites

- Optimize personnel required for archaeological expeditions

Data acquisition

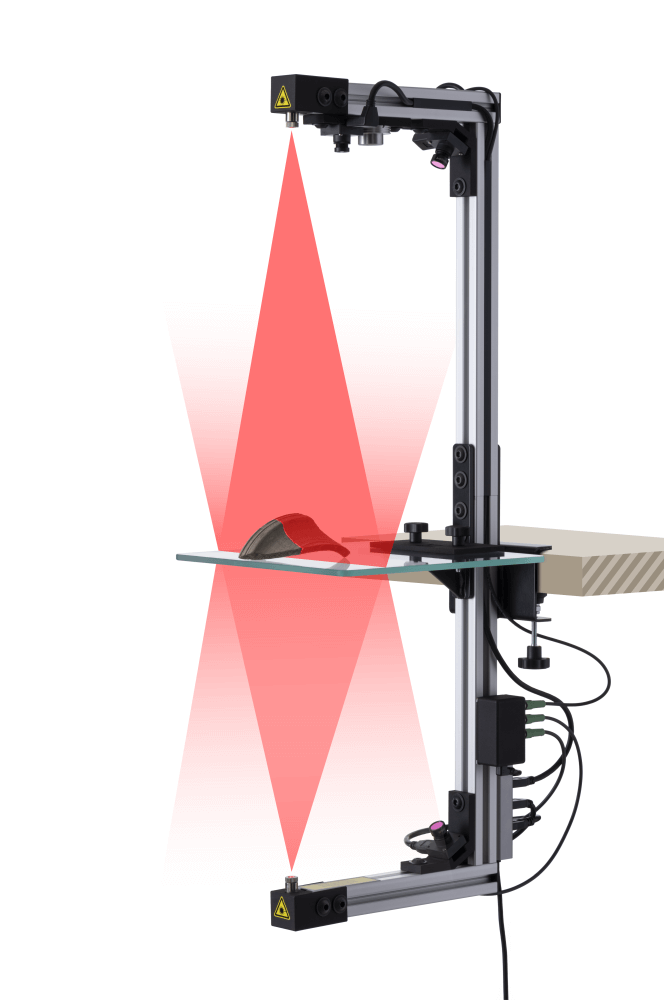

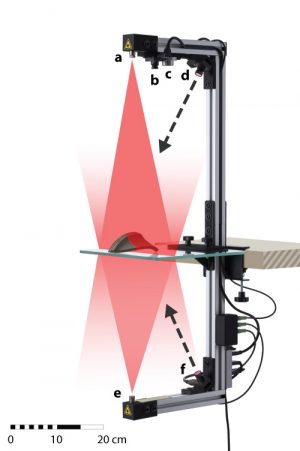

- LAP Laser Aided Profiler has Two laser modules (a, e) project visible lines onto the specimen from both sides. The scratch-resistant glass table ensures clear imaging even from below

- Using the sheet-of-light triangulation principle, 3D-cameras (d, f) capture the images of the laser lines to generate a complete section of the fragment in real time

- The 5-megapixel color camera (b) complements the drawing with standard photographic illustration. The illumination is provided by either the integrated high-power LED (c) or an external light source

Standard workflow

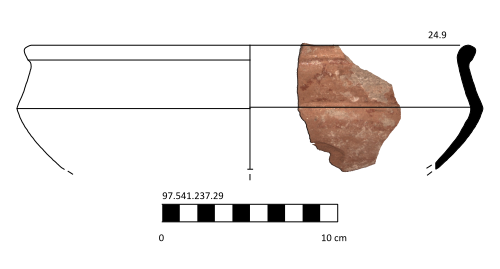

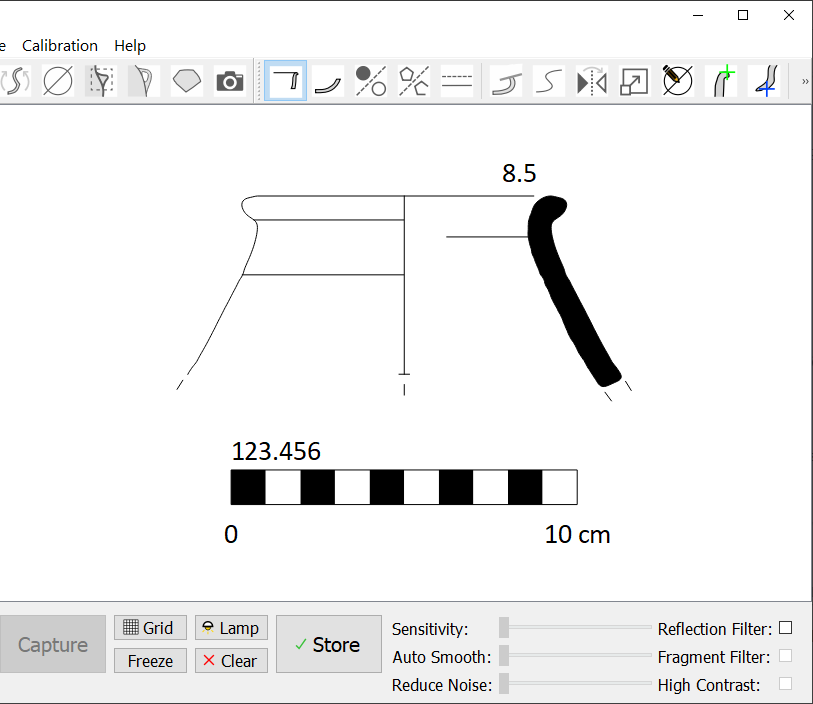

- The fragment to be scanned is manually positioned over the glass work surface by the operator or with the aid of the integrated helping hands. During the positioning, the profile is continuously evaluated and displayed live on the computer screen

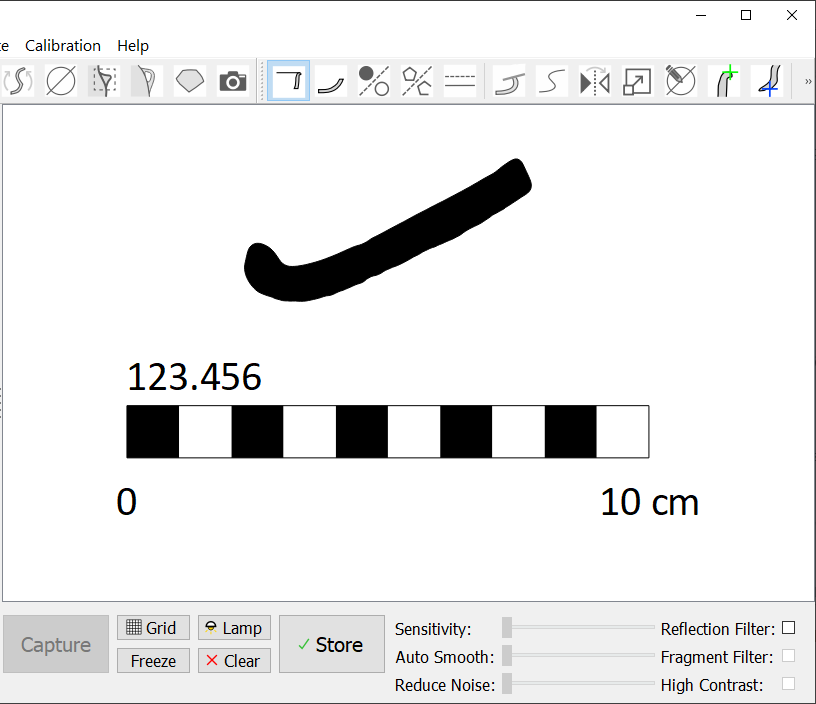

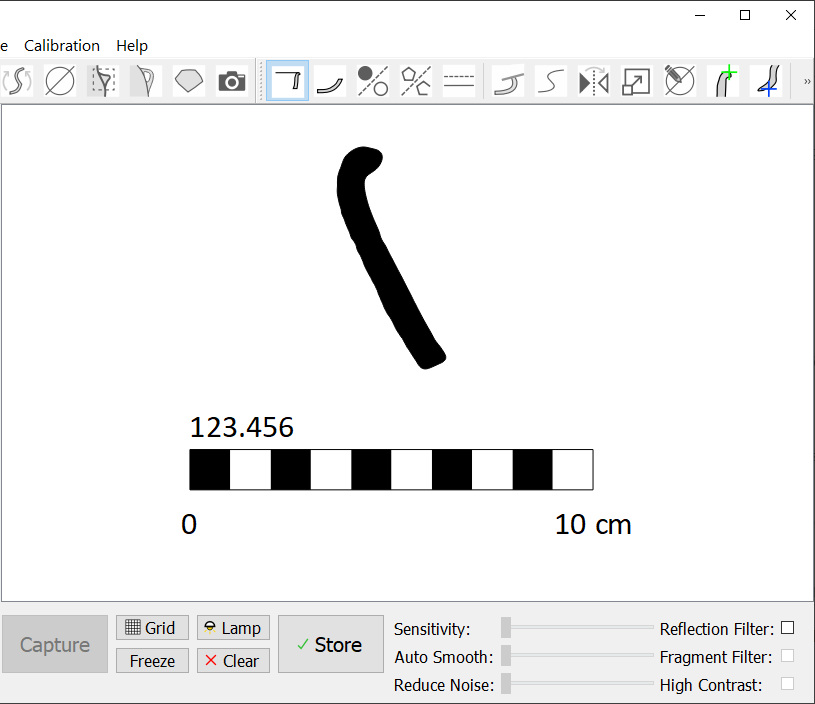

- In the first step, the operator takes the characteristic vertical cross section of the sherd

- After that, the profile orientation is set either manually or, if the vessel rim is preserved, by aligning the rim with the glass surface

- The horizontal profile is taken to determine the radius of the vessel at an arbitrary point

- Any additional details, such as handles or plastic elements, are acquired and aligned with the drawing

- The drawing is enhanced with inflection lines, break lines, annotations, and a color photograph of the sample

- The finished output is stored in a database for further processing or publishing

Data storage

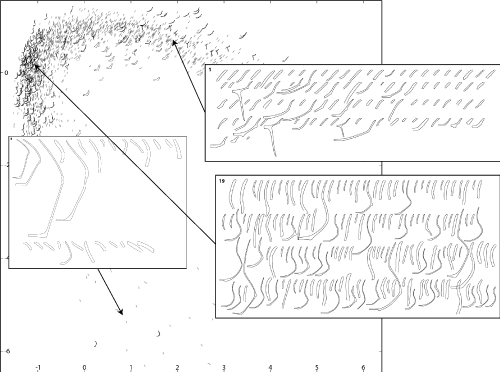

- Graph-based database Deposit stores finished drawings along the original acquired “raw” data and additional metadata

- Internal storage formats JSON or PostgreSQL

- Final drawings in SVG format with export options to PDF and PNG

- All data also available as polygons for custom analytic pipelines, e.g., shape matching or morphometrics

Photographic illustration

The LAP features a 5-megapixel color camera equipped with high-end optics for taking detailed pictures of the artifacts. The focus and depth of field are adjustable, enabling closeups and quick fine-tuning for shooting larger pieces.