High Speed Printing with High Performance Composite Materials

The Raise3D Pro3 HS Series supports 200-300 mm/s high-speed printing of composite materials, including the high performance Hyper Core filaments for end use applications, meeting the high standards and requirements from users, enhancing both production efficiency and part quality. As a result of this high performance composite material support, the resulting printed parts perform effectively even in the most demanding end-use applications.

- High Performance Composite Materials

- Open Filament Program

This improvement allows for high-speed printing of composite materials to meet advanced requirements. Additionally, the new auto filament switching function supports 2.5 kg filament spools, enabling manufacturers and print farms to efficiently and reliably produce small batches of end-use parts or tooling fixtures.

Tailored for high speed printing

The Pro3 HS series supports 200-300 mm/s high-speed printing of composite materials, including Hyper Core and Industrial high-performance materials, ensuring that the resulting printed parts perform effectively in demanding end-use applications. This capability enhances both production efficiency and product quality. Furthermore, the incorporation of Hyper FFF technology provides precise and reliable high-speed printing, featuring a high-flowrate hot end and an active vibration reduction algorithm.

The built-in Hyper FFF technology enables printing at standard speeds of 300 mm/s, even with Hyper Core high-performance materials, reducing printing time by 30 % to 70 % compared to existing Raise3D printer series with the Hyper FFF upgrade. The motion control system has been upgraded with a closed-loop stepper motor, double-diaphragm couplings, and an optimized axis structure, ensuring precise high-speed printing without losing steps and reducing noise by over 27 %.

Image 2: The upgraded motion control system of the Pro3 HS printer. Source: Raise3D.

Designed for high-volume industrial printing applications, the Raise3D Pro3 HS Series is optimized for reliability and durability. Its strengthened hot end and all-metal nozzle, combined with a proven all-metal frame and dual-gear extruder, enable long-hour production. The optical axis structure of the coupling in the transmission system improves tightness and durability, making the machine suitable for extended use. The new printing build plate provides a more uniform and powerful magnetic attraction to suppress model warpage and is thinner by 1 mm, heating up to 100 ºC two minutes faster, reducing waiting time and improving print efficiency.

Image 3: The RFID sensor identifies the filament and verifies necessary parameters. Source: Raise3D.

To maximize production efficiency with minimal manual intervention, the Pro3 HS Series features an automatic filament switching function for uninterrupted production up to 120 hours. It can print using two larger 2.5 kg filament spools, allowing continuous printing with up to 5 kg of material. The RFID sensor identifies the filament and verifies necessary parameters to prevent incorrect material usage, while the auto filament unloading function reduces manual intervention, increasing production efficiency and reducing labor involvement.

Image 4: The new dual head with electronic lifting system. Source: Raise3D.

The Raise3D Pro3 HS Series includes Hyper Core filaments, offering fast-melting and cooling rates for high-speed printing with improved Z-direction strength and stiffness. Each Pro3 HS printer comes with a high flowrate hot-end with a silicon carbide nozzle and a roll of Hyper Core filament, making composite printing more accessible. The Raise3D Pro3 HS Series stands out for its advanced features and capabilities, making it an excellent choice for professionals seeking reliable, high-speed, and efficient 3D printing solutions.

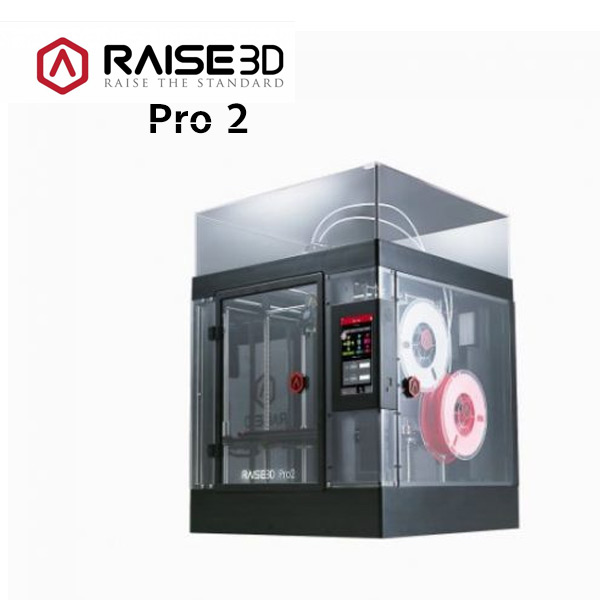

Compatible materials

The Raise3D Pro3 HS printer features generous printing parameters to accommodate various project sizes and complexities. With a build volume of 300 × 300 × 300 mm for single extruder prints and 255 x 300 x 300 mm for dual extruder prints, it offers ample space for large and intricate models. The printer’s nozzle can reach a maximum temperature of 320 ºC, while the heated bed can reach up to 120 ºC, ensuring compatibility with a wide range of materials and providing optimal conditions for high-quality prints for various applications.

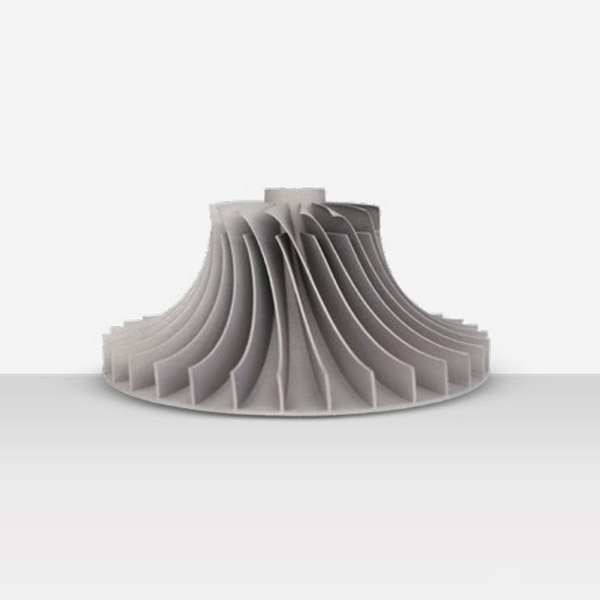

Image 5: Parts 3D printed on the Pro3 HS printer. Source: Raise3D.

It supports Hyper Core materials like PPA CF, PPA GF, and ABS CF, and Hyper Speed materials including PLA and ABS, ensuring high-speed printing with exceptional performance. Industrial-grade materials such as PPA CF, PPA GF, PET CF, PET GF, PETG ESD, PET Support, and PPA Support are also compatible, catering to demanding end-use applications.