Formlabs Form 3L – ΕΚΘΕΣΙΑΚΟΣ

11.159,00€ 4.900,00€ ME ΦΠΑ

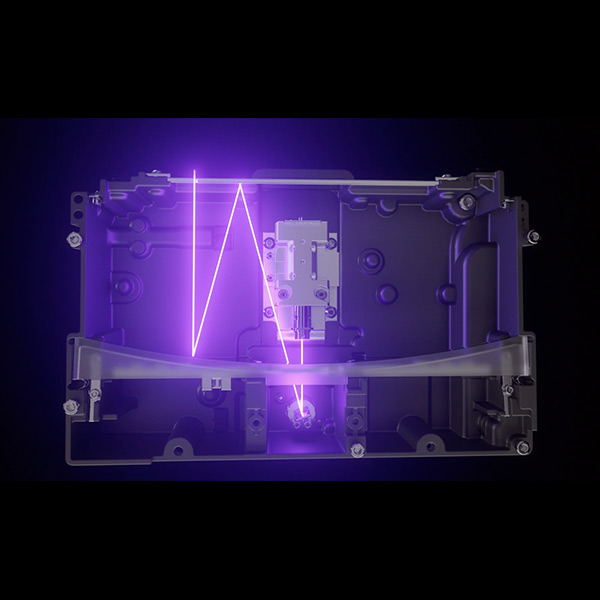

Oλοκαίνουριος επαγγελματικός εκτυπωτής Formlabs Form 3L και 3BL με νέα τεχνολογία Low Force Stereolithography, πολύ μικρότερο laser spot size με κάθετη προβολή του laser, 25microns ακρίβεια στον ΧΥ, flexible vat για ελαχιστοποίηση δυνάμεων στην αποκόλληση προσφέρει αξιοπιστία και πολύ εύκολα στο καθάρισμα μικρότερα supports, τεράστιο build volume 335 × 200 × 300 mm με 2πλό Laser Processing Unit, και πολλά ακόμα features που τον κατατάσουν στην κορυφή των επαγγελματικών SLA 3D Printer!

o 3BL διαφοροποιείται από τον 3L μόνο στο ότι υποστηρίζει επιπλέον και βιοσυμβατές ρητίνες για dental και medical devices.

Form 3L

A Large Format 3D Printer Compact Enough for the Office and Robust Enough for the Factory Floor

Take control of large-scale part production, increase your throughput, and bring your biggest ideas to life with the Form 3L, a cost-effective large format 3D printer that doesn’t compromise on the details.

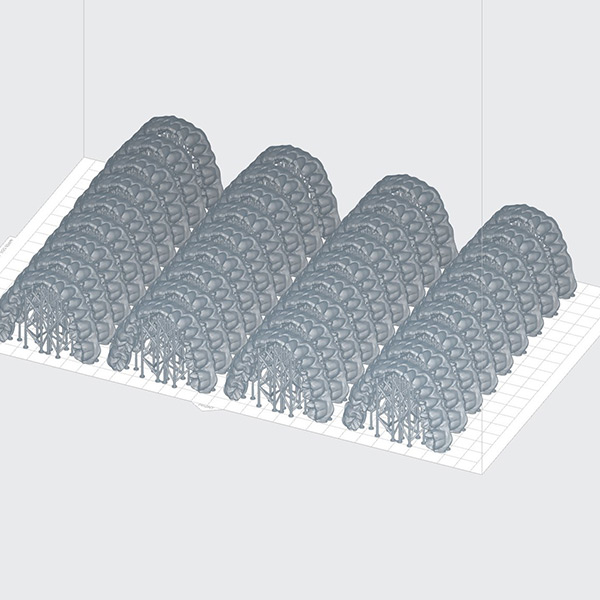

Big Parts, Big Throughput

With a large build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in), you can print one large model or many small parts in a single job.

![]()

Stop outsourcing large-scale prints.

Work faster with a large format 3D printer that’s versatile enough to bring large scale fabrication in-house.

![]()

Life-sized prints for larger-than-life ideas.

The Form 3L is large enough to print human-scale models, like a prototype of a helmet that’s ready to try on.

![]()

Perfectionism that scales.

Two precision Light Processing Units inside the printer achieve consistent accuracy and detail across the entire build platform.

Helmet

Black Diamond Equipment is prototyping climbing helmets at 1:1 scale to test for form and fit, producing several iterations per week in-house and reducing costs.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Nozzles

20 per build

Engineers and product designers can use the Form 3L to quickly prototype multiple variations of a design or produce dozens of product samples.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Jig

Adapter

65 per build

The Ventilator Project used Formlabs printers for emergency low volume production of this ventilator adapter, which is used to regulate airflow before it reaches a mass flow sensor.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Shovel

Black Diamond Equipment’s Evac 7 avalanche shovel is a configurable, compact three-piece assembly. The design team is able to immediately visualize design improvements where the fit and feel in the user’s hands is critical.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Enclosure

Minnetronix needed to create a display-worthy sample before starting manufacturing of a critical care ventilator as part of efforts to meet COVID-19 demand. They took advantage of the Form 3L to quickly produce the largest cosmetic part in the assembly, alongside other fabrication technologies.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Spoon

2 per build

Product developers at OXO use Formlabs 3D printers for form and function prototyping. 3D printing allows companies like OXO to try innovative design ideas quickly and ensure that ideas are fully tested and vetted before committing to tooling.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

TMNT

Visual effects and design studio Aaron Sims Creative uses 3D printed maquettes to facilitate collaboration, win over producers and directors, and bring digital models to life.

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Intuitive and efficient

No specialized technicians required. The Form 3L offers automatic resin dispensing, simple print preparation software, and a thoughtfully designed interface.

High-resolution touchscreen interface:

A 5.5” interactive full-color display minimizes error and eliminates the need for constant monitoring.

Automated print setup:

Tested over millions of prints, our free print preparation software, PreForm, automatically suggests optimal orientation, supports, and layout, with the ability to manually refine as needed.

Continuously evolving:

We believe the best products grow better over time, and we’re committed to continually evolving our hardware through software improvements.

Print around the clock

Whether you’re packing the build volume for batch production or printing bulky parts, the Form 3L maintains ideal print conditions for nonstop throughput, with minimal supervision.

Cloud monitoring:

Remotely monitor and manage your fleet of printers with the online Dashboard.

Fast-printing material:

Draft Resin balances detail and speed to save time on bulky prototypes and enable quick iteration.

In-field repairs:

The Light Processing Units, rollers, optics window, and other components can be replaced in-house to ensure 24/7 uptime.

Incredible part quality

Stop sacrificing on quality for large-format prints. The Form 3L provides the smooth surface finish and fine detail that stereolithography 3D printing is known for.

Smooth surface finish:

Models printed on the Form 3L resemble polished injection-molded for realistic looks-like prototyping and consumer-ready end-use part production.

Consistent precision:

A system of lasers and mirrors ensures uniform print quality, for an XY resolution of 25 microns across the entire build platform.

High translucency:

With precise layer registration and smooth surface finish, translucent materials print clearer than ever, right off the printer.

Hassle-Free Materials Management

Choose from a wide range of advanced materials, developed specifically for Formlabs printers by in-house materials scientists. With simplified material switching and automatic resin dispensing, the Form 3L allows you to walk away and focus on other work once your print job starts.

![]()

Many applications, one printer.

Print in over 15 functional resins to support a wide range of workflows on a single platform.

![]()

Switch materials in minutes.

Avoid the hassle and mess of purging materials with our swappable cartridge system, cross-compatible with other Formlabs SLA printers.

![]()

Automatic resin dispensing.

Our automated resin system dispenses resin as parts print. The Form 3L holds two cartridges of resin to avoid mid-print interruptions.

Tech Specs

| Printer | Form 3+ | Form 3L | Form 3BL |

| Technology | Low Force Stereolithography (LFS)™ | Low Force Stereolithography (LFS)™ | Low Force Stereolithography (LFS)™ |

| XY Resolutionᵃ | 25 microns | 25 microns | 25 microns |

| Laser Spot Size | 85 microns | 85 microns | 85 microns |

| Laser Power | One 250 mW laser | Two 250 mW lasers | Two 250 mW lasers |

| Build Volume (W x D x H) | 14.5 × 14.5 × 18.5 cm 5.7 × 5.7 × 7.3 in |

33.5 × 20 × 30 cm 13.2 × 7.9 × 11.8 in |

33.5 × 20 × 30 cm 13.2 × 7.9 × 11.8 in |

| Layer Thicknessᵇ | 25 – 300 microns .001 – .012 in |

25– 300 micronsᶜ .001 – .012 in |

25 – 300 micronsᶜ .001 – .012 in |

Printing Properties

| Printer | Form 3+ | Form 3L | Form 3BL |

| Technology | Low Force Stereolithography (LFS)™ | Low Force Stereolithography (LFS)™ | Low Force Stereolithography (LFS)™ |

| Resin Fill System | Automated | Automated | Automated |

| Build Volume (W x D x H) | 14.5 × 14.5 × 18.5 cm 5.7 × 5.7 × 7.3 in |

33.5 × 20 × 30 cm 13.2 × 7.9 × 11.8 in |

33.5 × 20 × 30 cm 13.2 × 7.9 × 11.8 in |

| Layer Thickness (Axis Resolution)ᵇ | 25 – 300 microns .001 – .012 in |

25– 300 micronsᶜ .001 – .012 in |

25 – 300 micronsᶜ .001 – .012 in |

| XY Resolutionᵃ | 25 microns 0.001 in |

25 microns 0.001 in |

25 microns 0.001 in |

| Laser Spot Size | 85 microns 0.0033 in |

85 microns 0.0033 in |

85 microns 0.0033 in |

| Resin Cartridges | 1 | 2 | 2 |

| Biocompatible Materials | No (available on Form 3B+) | No (available on Form 3BL) | Yes |

| Supports | Auto-Generated Light-Touch Removal |

Auto-Generated Light-Touch Removal |

Auto-Generated Light-Touch Removal |

Hardware

| Printer | Form 3+ | Form 3L | Form 3BL |

| Minimum Access Dimensions (W × D × H) | 40.5 × 53 × 78 cm 15.9 × 20.9 × 30.7 in |

90 × 96 × 104 cm 35.4 × 37.8 × 41 in |

90 × 96 × 104 cm 35.4 × 37.8 × 41 in |

| Printer Dimensions (W × D × H) | 40.5 × 37.5 × 53 cm 15.9 × 14.8 × 20.9 in |

77 × 52 × 74 cm 30.3 × 20.5 × 29.1 in |

77 × 52 × 74 cm 30.3 × 20.5 × 29.1 in |

| Weight | 17.5 kg 38.5 lbs |

54.4 kg 120 lb |

54.4 kg 120 lb |

| Internal Temperature | Auto-heats to 35 °C Auto-heats to 95 °F |

Auto-heats to 35 °C Auto-heats to 95 °F |

Auto-heats to 35 °C Auto-heats to 95 °F |

| Temperature Control | Air-heated print chamber | Air-heated print chamber | Air-heated print chamber |

| Operating Environment | 18 – 28 °C 64 – 82 °F |

18 – 28 °C 64 – 82 °F |

18 – 28 °C 64 – 82 °F |

| Power Requirements | 100–240 VAC 2.5 A 50/60 Hz 220 W |

100–240 VAC 8.5A MAX 50/60HZ 650W |

100–240 VAC 8.5A MAX 50/60HZ 650W |

| Laser Specifications | 1 Light Processing Unit EN 60825-1:2007 certified Class 1 Laser Product 405 nm wavelength 250 mW power 85 micron (0.0033 in) laser spot |

2 Light Processing Units EN 60825-1:2007 certified Class 1 Laser Product 405 nm wavelength 250 mW power 85 micron (0.0033 in) laser spot |

2 Light Processing Units EN 60825-1:2007 certified Class 1 Laser Product 405 nm wavelength 250 mW power 85 micron (0.0033 in) laser spot |

| Connectivity | Wi-Fi (2.4, 5 GHz) Ethernet (1000 Mbit) USB 2.0 |

Wi-Fi (2.4, 5 GHz) Ethernet (1000 Mbit) USB 2.0 |

Wi-Fi (2.4, 5 GHz) Ethernet (1000 Mbit) USB 2.0 |

| Printer Control | 5.5″ interactive touchscreen 1280 × 720 resolution |

5.5″ interactive touchscreen 1280 × 720 resolution |

5.5″ interactive touchscreen 1280 × 720 resolution |

| Alerts | Touchscreen alerts SMS/email via Dashboard Two LED status indicators Speaker for audio alerts |

Touchscreen alerts SMS/email via Dashboard Two LED status indicators Speaker for audio alerts |

Touchscreen alerts SMS/email via Dashboard Two LED status indicators Speaker for audio alerts |

Software

| System Requirements | Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM (8 GB recommended) |

| Hardware Requirements | Form 3+, Form 3B+, Form 3L, Form 3BL, Form 3, Form 3B, or Form 2 3D printer |

| File Types | STL and OBJ file input FORM file output |

| PreForm Print Setup Features | One-Click Print Adaptive layer thickness for faster printing with fine details Remote Print Auto-orient for optimal print position Auto-mesh repair Auto-generation of supports Rotate, scale, duplicate, and mirror Layer slicer for path inspection Available in multiple languages |

| Dashboard Printer Management Features | Manage prints and printers via the cloud Track resin and tank usage over time SMS and email alerts Create enterprise group accounts with admins to more easily share printers and control access |

Form 3BL

Large Medical Devices and Anatomic Replicas at Full Scale

3D print adult patient anatomy at 1:1 scale, large medical devices, or multiple parts in one build with the Form 3BL, a large format 3D printer developed for healthcare. This 3D printer is compatible with the majority of our SLA materials library, including biocompatible, sterilizable materials.

Big Parts, Big Throughput

With a large build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in), you can print one large model or many small parts in a single job.

Life-sized 3D prints.

The Form 3BL is large enough to print full size anatomy and medical devices. With a 19.4” diagonal, print adult femurs, pelvic bones, skulls, and more at 1:1 scale.

On-demand printing.

From time-sensitive point of care printing to groundbreaking medical devices, work faster and with full control with a versatile, large format 3D printer in house.

Validated Workflows.

The Form 3BL has been validated in FDA-cleared workflows. It is also compatible with a wide range of biocompatible, sterilizable materials manufactured in an ISO 13485 certified facility.

Form 3BL is ideal for:

Large parts requiring biocompatibility and sterilization compatibility

Medical device prototypes, jigs, fixtures, assemblies, and end-use parts

Surgical planning models for diagnostic use in FDA-cleared workflows

Full-size, anatomical models at 1:1 scale, including pediatric and adult anatomy

Surgeon-specific or patient-specific surgical tools

Ventilator Enclosure

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Scoliotic Rib Cage (2 parts)

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Cranium

Adult Humerus

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Intuitive and efficient

Seamlessly integrate the Form 3BL into your existing clinical workflows – no specialized technicians required. With automatic resin dispensing, simple print preparation software, and a thoughtfully designed interface, the Form 3BL is designed for efficiency.

Always on call

The Form 3BL works around the clock with minimal supervision required. With compatability with our entire SLA materials library, sensors that maintain ideal print conditions, and remote printing, the Form 3BL helps you meet critical deadlines, even for trauma surgery. Acheive multicolor parts using various techniques.

Incredible part quality

The Form 3BL resolves fine details down to the micron level, critical when using surgical planning models for diagnostic use, while the smooth surface finish and high accuracy of the Form 3BL ensures medical devices meet production standards.

Επιπλέον πληροφορίες

| Επιλογή Μοντέλου: | 3L (όλες οι ρητίνες εκτός τις βιοσυμβατές), 3BL (όλες οι ρητίνες και οι βιοσυμβατές) |

|---|

Related Products

Formlabs Form Auto

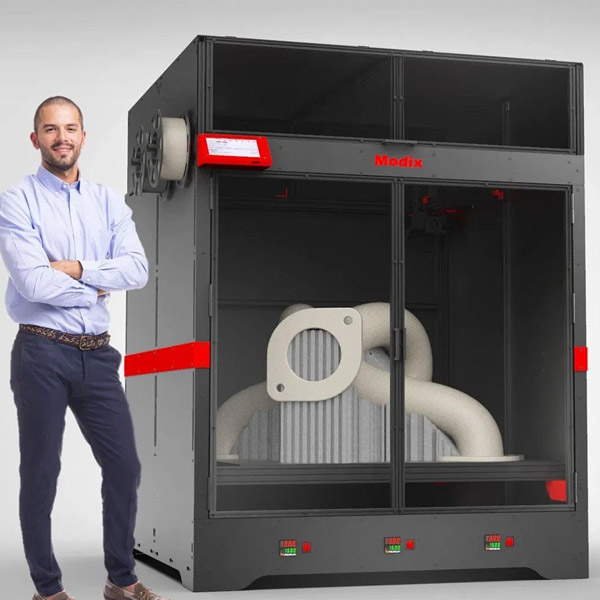

4.215,00€ ME ΦΠΑModix BIG 120X V4 (ΚΙΤ)

10.699,00€ ME ΦΠΑMODIX BIG 180X (KIT)

21.299,00€ ME ΦΠΑRaise3D Pro3

Raise3D Pro2

MODIX BIG Meter (KIT)

18.799,00€ ME ΦΠΑ