Anisoprint Composer A3 / A4 Continuous Fiber 3D Printers

Reduce the cost and weight of jigs, fixtures and end-use parts, while maintaining mechanical properties, with the Composer A4 from Anisoprint.

Unique Composite Fibre Coextrusion (CFC) technology allows the printing of continuous carbon fibre directly into a 3D printed part, significantly increasing part strength when compared with printing polymers alone.

The Composer works both with the patented CFC technology (Composite Fiber Coextrusion) and with standard FFF 3D printing technology. Composer A3 enables the production of optimized composite structures that are characterized by high physical and mechanical properties. The end parts are stronger and lighter than parts with similar properties that are made with metal, thermoplastics or non-optimized composites. They can also be manufactured at a lower cost.

Features Anisoprint Composer A4 & A3

- FFF and CFC extruders

- LCD touch screen

- Dual-nozzle system

- Removable print bed

- Strong and lightweight printing products

- CFC extruder with cutting device for reinforcing fibers

- Print bed size 420 mm х 297 mm х 210 mm

- 60 micron resolution

Anisoprint Composer enables you to enter the era of long-fiber composite materials

- continuous fiber reinforced composites: 30 times stronger than pure plastic, 2 times stronger and lighter than aluminum

- optimal composite structures: lattice reinforcement – minimal weight, price and production time for the required strength

2 SIZES

- A3 format: 420 mm х 297 mm х 210 mm build volume

- A4 format: 297 mm х 210 mm х 140 mm build volume

- open material system: use any plastic (up to a melting temperature of 270 °C)

- two reinforcement materials: CCF (carbon-based) and CBF (basalt-based)

- Complete control over the creation of the fiber path with the slicing software Aura

COMPOSITE FIBER COEXTRUSION

The thermoplastic is reinforced with composite fibers during printing. The extruder has two inputs: one for reinforcing material and the other for the thermoplastic. Any plastic with a ptinting temperature of up to 270 ° C can be used (e.g. PETG, ABS, PC, PLA, nylon, etc.).

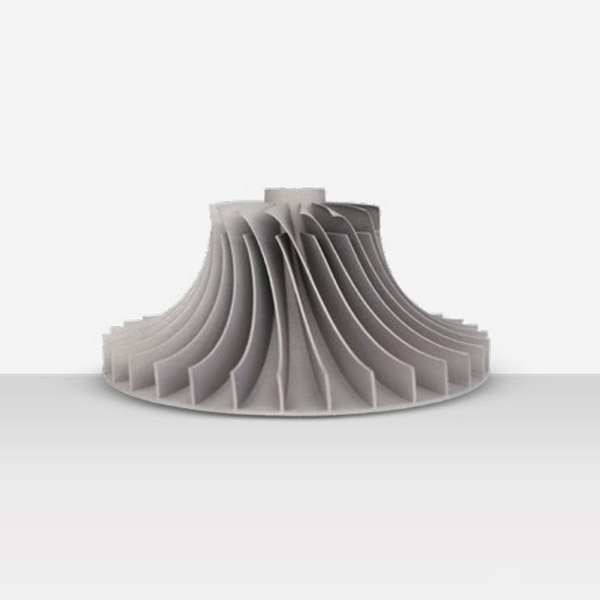

The strength and rigidity of the composite material lie along the fiber, which is why the grids, which consist of one-dimensional grid, represent the optimal shape for composite materials. The composite filling gives you maximum strength with minimal use of materials, i.e. minimal weight, minimal production time and minimal price of the printed component.

What is anisoprinting?

Anisoprinting is a technology for producing optimal composite structures using 3D continuous fiber printing.

The solution is based on the patent-pending composite fiber coextrusion technology (CFC). Various thermoplastic polymers can be reinforced, solidified, and cured with continuous filaments in a one-step, fully automated process that does not require post-processing or tooling. The two-matrix approach (thermoset + thermoplastic) ensures low porosity, good adhesion of the fiber to the polymer and superior mechanical properties.

With the Anisoprint Composer, you can print end-use parts that are stronger, lighter and cheaper than their counterparts made of other materials (metal, plastic, non-optimal composite materials).