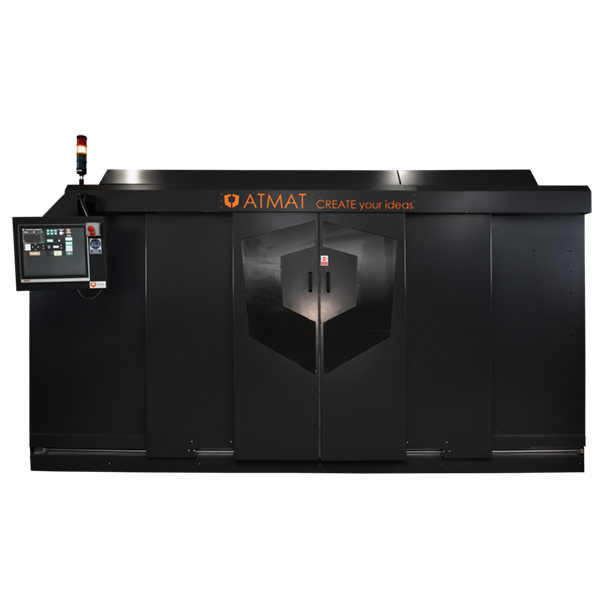

HP Jet Fusion 5200 Series

Mε πολύ μεγάλη υπερηφάνεια ανακοινώνουμε τη συμφωνία της 3DHUB Greece για την διάθεση των διάσημων βιομηχανικών 3D printing λύσεων της HP Inc. στην ελληνική αγορά! H διάθεσή τους γίνεται σε συνεργασία με την Active Computer Systems, η οποία και αποτελεί μακράν τον κορυφαίο συνεργάτη της HP Inc. στην χώρα μας με τεράστια εμπειρία στο 2D printing και το computing. H 3DHUB Greece έχει διεθνώς αναγνωρισμένη εξειδίκευση στο 3D Printing και στο νέο σχήμα συνδυάζεται η συσσωρευμένη τεχνογνωσία και εμπειρία των στελεχών της με την τεράστια δυναμική και διασπορά της Active Computer Systems, για την καλύτερη δυνατή αντιπροσώπευση των τεχνολογιών της HP Inc. στην χώρα μας με τη σύσταση της νέας θυγατρικής YLEM AE .

Επικοινωνήστε μαζί μας για να σας αναλύσουμε τα πλεονεκτήματα της MJF τεχνολογίας και πως μπορεί να βοηθήσει την επιχείρησή σας. Διαθέσιμος για να επιτόπια επίδειξη των δυνατοτήτων του στο υπερσύγχρονο 3D Print Lab μας στις εγκαταστάσεις της YLEM

– o MJF 5200 είναι το τελευταίο και πιο γρήγορο μοντέλο της MJF σειράς της HP, παρέχοντας build volume 380 x 284 x 380 mm, δυνατότητα εκτύπωσης ενός full κάδου με εκατοντάδες parts σε 11 ώρες στα 80microns, εξωτερική μονάδα Post Process, δυνατότητα άμεσης επανεκτύπωσης καθώς ο κάδος κρυώνει εκτός του εκτυπωτή και φυσικά παράγει τελικά functional parts με ποιότητα πολύ κοντά στο injection molding!

Unlock the full potential of 3D printing

Hp Multi Jet Fusion technology is based on polyamide grade materials called PA 11, PA 12 and PA Glass Beads. In addition, ULTRASINT 3D TPU01, a thermoplastic polyurethane material manufactured by BASF in accordance with the new HP MJF 5200 series, is used to produce flexible and elastomeric applications. This new material is well suited for the automotive, industrial and consumer industries, for applications requiring good shock absorption, energy return and flexibility.

With its innovative approach, HP Jet Fusion 3D Printer offers both 3D and material-oriented solutions to the 3D printer industry. 10 times faster with 30 million drops per second, delivering the best print quality, reusability, easy material change, production at low cost per piece thanks to HP’s own 3D printing materials.The thermal control of each layer on a voxel basis allows optimum mechanical properties to be achieved in the manufactured parts. HP Jet Fusion’s cooling module reduces printing time and enables faster parts production.

Print functional parts with maximum quality

With the 5200, you can mass produce functional parts with best-in-class isotropy and fine detail, sharp edges and textures. Equipment uptime is maximized with redundant components, preventive maintenance and our top of the line support.

Print times are predictable and consistent for any type of part. The 5200 features a streamlined workflow and HP’s most economical continuous 3D printing, with automated materials mixing, enclosed processing station, and a natural cooling unit.

You can address more end-use part applications with new levels of repeatable accuracy and best-in-class economics. With a broad materials portfolio, you can cater to a wide range of applications for various markets with HP 3D High Reusability PA 11 and PA 12 materials. You can also produce applications with flexible, elastomeric properties with TPU material. The materials portfolio grows continually, to enable you to target new industry applications and verticals.

Why choose HP Jet Fusion 5200?

- Produce parts with the accuracy and repeatability of injection molding

- Ramp up existing production with a solution designed for production runs in the tens of thousands of parts

- Integrated and user-friendly end-to-end industrial 3D printing solution

- Ideal for mid-volume production environments

Features

- Technology: HP Multi Jet Fusion technology (MJF)

- Build volume: 380 x 284 x 380 mm

- Processing Speed: 5058 cm3 / h

- Layer thickness: 0.08 mm

- Materials: PA11, PA12, BASF Ultrasint 3D TPU

HP Jet Fusion Fast Cooling and Processing Station

Features: Automatic mixer, sifter and loading; Semi-automatic extraction; fast cooling; external material tank