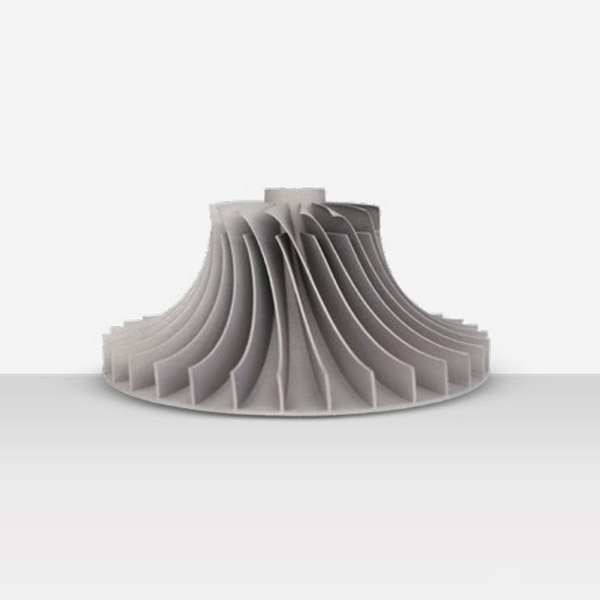

Groundbreaking Speed

Production is now much faster with the HP Jet Fusion 3D 3200/4200, which halves material costs 10 times faster than SLS and 25 times faster than FDM. The HP Jet Fusion 3D is capable of making cooling outside the construction unit, preventing the product from being produced, and continuously producing 24 hours a day with both faster cooling and construction.