3D Printer Delta Wasp 3MT

Delta WASP 3MT CONCRETE is manufactured in metal with strong steel cored belts and is equipped with special grid panels to work in complete safety.

With this big dimension 3D printer is possible to create concrete mortar products thanks to an innovative extrusion system equipped with a special mortar pump and a screw-driven extruder.

Furthermore the MDF pallet bed and the removable front lower beam allow to remove, once the printing activity is completed, the objects printed both via pallet truck and forklift.

Delta Wasp 3MT Concrete

With a build area of big dimension and its unique versatility, concrete 3D printer Delta WASP 3MT CONCRETE defines a new standard in the world of additive manufacturing of concrete mortars.

* With kit LDM WASP Extruder XXL – CONTINUOUS FEEDING SYSTEM

BUILDING INDUSTRY

Housing

Special Prefab

R&D LAb concrete centers

EDUCATION CENTERS

Universities

Research Centres

ARCHITECTS STUDIOS

Temporary pavilion

Urban furniture

Landscape works

Infrastructures

CERAMICS INDUSTRY

Ceramic cladding

Bathroom fixture

Decorative elements

ΤΕΧΝΙΚΕΣ ΛΕΠΤΟΜΕΡΕΙΕΣ

ΠΛΗΡΟΦΟΡΙΕΣ 3D ΕΚΤΥΠΩΣΗΣ

Build volume Ø 1000 x h 1000 mm (h max 1000 mm, from the ground)

Print speed max 200 mm/s

Travel speed max 200 mm/s

Acceleration 150 mm/s2

Nozzle diameter (LDM WASP EXTRUDER XL) Ø 4 – 6 – 8 mm

Nozzle diameter (LDM WASP EXTRUDER XXL) Ø from 8 to 30 mm

Advised nozzles:

Concrete, Earth based materials Ø from 18 to 30 mm

Clay Ø from 8 to 18 mm

ΥΛΙΚΑ

Suitable materials

LDM WASP EXTRUDER XXL Ø from 8 to 30 mm

concrete mortars with max particle size 1 mm, fiber reinforced concrete (polymeric fibres, Lmax 30 mm; Wmax 15 kg/mc), foamed concrete, clay, porcelain, gres, earth based mixtures with natural fibres.

LDM WASP EXTRUDER XL Ø 4 – 6 – 8 mm

clay, porcelain, gres

WASP 3D CONCRETE:

Supply of cementitious pre-mixed mortars and mixtures improved and tested for 3D printing.

Test on property materials for 3D printing, consultancy and in-depth analysis of technical aspects oriented to design and 3D printing on architectural size.

ΠΑΡΑΜΕΤΡΟΠΟΙΗΣΙΜΑ ΕΡΓΑΛΕΙΑ

LDM WASP Extruder XXL* screw extruder for big and fast prints with clay and concrete

Nozzle diameter: Ø from 8 to 30 mm

*standard tool with printer

LDM WASP Extruder XL screw extruder for precise and high-quality prints with clay

Nozzle diameter: Ø 4 – 6 – 8 mm

PUMPING SYSTEM

With the LDM WASP Extruder XXL kit – Continuos Feeding System WASP supplies the printer with a mortar pump for cement:

TECHNICAL FEATURES

Load volume 80 L

Length of supplied tube 5 m

Maximum pressure 35 bar

Maximum granulometry 1 mm

Maximum flow 250 L/h

Dimensions (L x b x h) 140 x 70 x 81 cm

Machine weight 185 kg

Frame material Steel

Input power 220/240 V 50/60 Hz

Motor power 2200 W

Packaging in wooden box for national/international shipping.

Box C 140 x 80 x 120, weight: 15 kg

ΛΟΓΙΣΜΙΚΟ

Operative system WIndows, Mac, Linux;

Simplify3D® License included, compatible with all slicing softwares(Cura – SLic3r)

File type .stl, .obj, .gcode

ΠΕΡΙΒΑΛΛΟΝ ΕΡΓΑΣΙΑΣ

Pendrive USB

Wifi network

Display TFT touch

ΦΥΣΙΚΕΣ ΔΙΑΣΤΑΣΕΙΣ

Dimensions 215 cm x 235 cm x 305 cm

Machine weight 350 kg

The machine travels disassembled and it’s assembled in the work space by our technicians only. The required space for assembly is: 5,5 mt x 2,5 mt x h 3,60 mt.

Packaging in wooden box for national/international shipping

Box A 310 x 60 x 55 cm – weight 63 kg

Box B 227 x 60 x 150 cm – weight 82 kg

ΤΡΟΦΟΔΟΤΙΚΟ

Input 220/240 V 50/60 Hz

Absorbed power:

Delta WASP 3MT INDUSTRIAL 4.0 LDM + LDM WASP EXTRUDER XXL – CONTINUOUS FEEDING SYSTEM 3,4 KW

Delta WASP 3MT INDUSTRIAL 4.0 LDM + LDM WASP EXTRUDER XL 1,2 KW

ΘΕΡΜΟΚΡΑΣΙΑ

Χρήση: 15-30 C°;

Αποθήκη: 0-30 C°;

ΜΗΧΑΝΙΚΑ

Frame and cover aluminum, painted steel. Metal carters, defeats machine’s vibrations, allows a more precise machine.

Bed MDF plate upon pallet.

Movements nylon wheels on anodized aluminum sliders steel-cored belts in delrin.

Insulation expanded polymer for acoustic insulation.

Motors axes Stepper

INCLUDED MATERIAL

LDM WASP EXTRUDER XXL

Plastic conical nozzles

Mortar pump 80 L

Tube 5 m

MDF plate upon pallet

The machine travels disassembled and it’s assembled in the work space by our technicians only. The required space for assembly is: 5,5 mt x 2,5 mt x h 3,60 mt. Packaging in wooden box for national/international shipping:

Box A 310 x 60 x 55 cm – weight 63 kg

Box B 227 x 60 x 150 cm – weight 82 kg

Box C* 140 x 80 x 120 cm – weight: 15 kg

*Pump for the LDM WASP Extruder XXL kit

TECHNICAL INNOVATION

WIFI machine connected to the network for monitoring and control.

Industria 4.0 3D printer with CE certification for compatibility with Industry 4.0 incentives.

New GUI new touch interface with bigger TFT display.

Camera on-board for monitoring and timelapse.

Remote intervention WASP technicians can follow you step-by-step remotely.

Continuous feeding system innovative system for material feeding, interconnected to pressure sensor.

Industrial tools

This concrete 3D printer, Delta WASP 3MT INDUSTRIAL 4.0 LDM is optimized for large 3D printing and can be configured with the following tools:

LDM WASP Extruder XXL* screw extruder for cement mortars, mixtures based on raw earth and natural fibers and clay based mixtures with continuous feeding system.

Nozzle diameter: from 8 to 30 mm.

Clay: 8 – 18 mm

Cement mortars and natural mixtures: 18 – 30 mm

* Tool standard with the printer

LDM WASP Extruder XL screw extruder for dense fluid materials: clay, porcelain, stoneware with 3/5 kg tank.

Nozzle diameter: 4 – 6 – 8 mm.

LDM WASP EXTRUDER XXL

With continuous feeding system

Concrete mortars, Raw Earth and natural fibers, Clay

Ø from 8 to 30 mm

LDM WASP EXTRUDER XL

With 3/5 kg tank

Clay, Porcelain, Stoneware

Ø 4 6 8 mm

ΧΑΡΑΚΤΗΡΙΣΤΙΚΑ

CONTINIOUS FEEDING SYSTEM

MULTI MATERIAL

REAL-TIME PRESSURE CONTROL

OPEN DOOR SAFETY SENSOR

SAFETY GRID

MDF BED ON PALLET

EASY TO PICK UP

KIT XL COMPATIBLE

WIFI MODULE FOR REMOTE CONTROL

ΣΥΣΤΗΜΑ RESURRECTION (cc)

ACOUSTIC INSULATION PANELS

ΤΡΙΑ ΜΠΡΑΤΣΑ ΣΤΑΘΕΡΟΠΟΙΗΣΗΣ

HIGH PRECISION SLIDER

STEEL CORED BELTS FOR HIGH SLIDING

NEW 32 BIT BOARD X4 POWER

Continuous Feeding System

The LDM WASP Extruder XXL is feeded using a mortar pump that delivers the material through a tube. The flow rate is controlled via a pressure sensor mounted on the extruder inlet, that is capable of continuously measuring the pressure and therefore the flow of outbound material in order to achieve the best extrusion conditions. By using the pump control unit, all the pumping variables can be set according to the type of material and to the paste consistency.

Concrete 3D Printer

Delta WASP 3MT CONCRETE is manufactured in metal with strong steel cored belts and is equipped with special grid panels to work in complete safety.

With this big dimension 3D printer is possible to create concrete mortar products thanks to an innovative extrusion system equipped with a special mortar pump and a screw-driven extruder.

Furthermore the MDF pallet bed and the removable front lower beam allow to remove, once the printing activity is completed, the objects printed both via pallet truck and forklift.

WASP Consultancy

From the experience gained in the field of 3D design and fluid-dense construction materials developed for 3D printing, WASP provides long-term consultancy for the optimization of the production process.

- Supply of pre-mixed cement mortars and natural mixtures developed for 3D printing;

- Experimentation of proprietary materials for 3D printing;

- Technical consultancy for the design for 3D printing and 3D slicing.

WASP PLUS +

HUGE VOLUMES

Ø 1000 mm x h 1000 mm = 1000 l

CONTINUOUS FEEDING SYSTEM

Compatible with automatic continuous mixer

REAL-TIME PRESSURE CONTROL

Real-time control of pumping and extrusion variables

FLOW MAX

250 litre/h

XXL SCREW EXTRUDER

Retraction control in extrusion

MULTI – MATERIAL

Concrete – Natural Mixtures – Clay

WIFI MODULE

Machine connected to the network for monitoring and control

ΣΥΣΤΗΜΑ RESURRECTION

Ένα σύστημα που επιτρέπει στους χρήστες να αποθηκεύσουν την εργασία εκτύπωσης για να την συνεχίσουν σε περίπτωση διακοπής ρεύματος.

ΣΥΣΤΗΜΑ FREE Z

Το μηχάνημα μετρά το ύψος της διακοπής της εκτύπωσης και κάνει επανεκκίνηση εκεί.

Industry 4.0

3D printer with CE certification for compatibility with Industry 4.0 incentives. Delta WASP 3MT INDUSTRIAL 4.0 LDM can be connected to Wi-Fi network so that you can manage your printer from smartphone, tablet or PC. Inside the printer there’s now a camera for monitoring the print even from remote.3

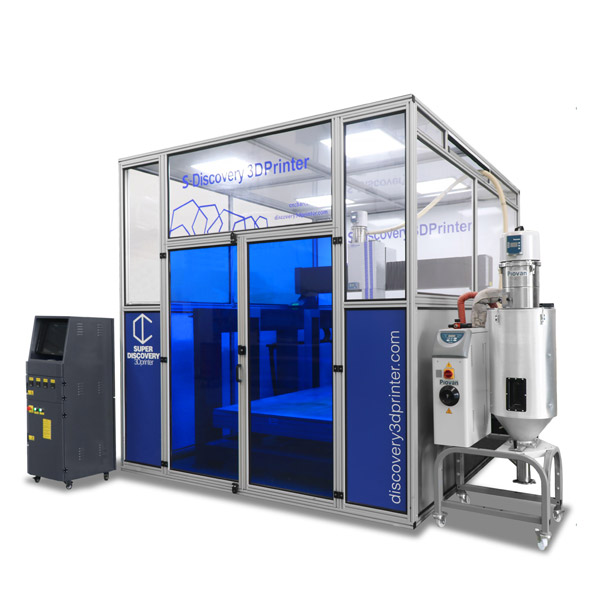

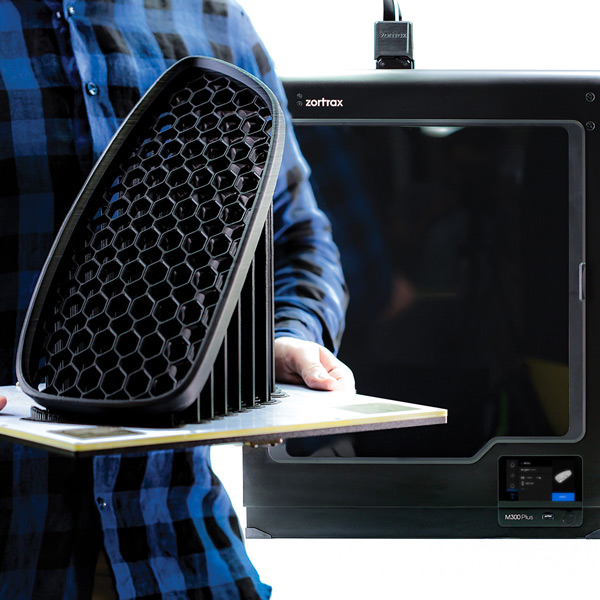

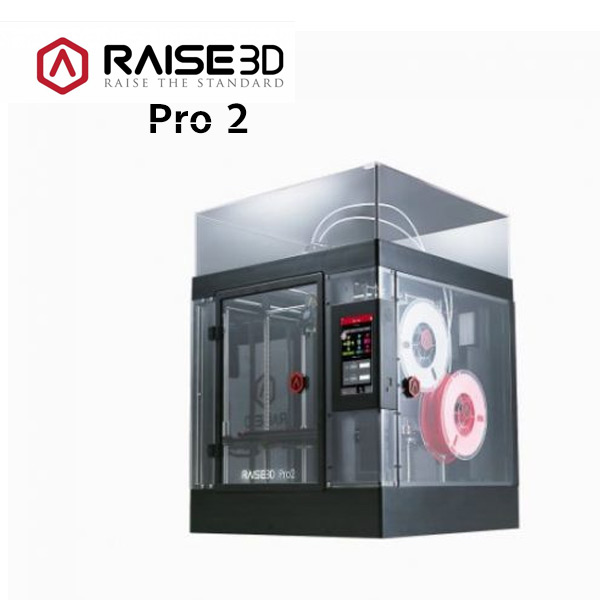

Related Products

Zortrax M300 Dual

4.999,00€ – 5.299,00€ ME ΦΠΑFormlabs Form 3L – 3BL

11.159,00€ – 15.499,00€ ME ΦΠΑZortrax M300 Plus

Raise3D Pro2

Foodini 3D Printer

7.990,00€ ME ΦΠΑ