BASF Ultrafuse 316L 3kg

479,00€ ME ΦΠΑ

Το BASF Ultrafuse 316L φέρνει την εκτύπωση μετάλλου στον οικιακό ή επαγγελματικό σας FDM εκτυπωτή. Τα τρισδιάστατα εκτυπωμένα αντικείμενα αποκτούν τις τελικές τους ιδιότητες όπως σκληρότητα και αντοχή μέσω μίας πρότυπης διαδικασίας debinding και sintering που έχει αναπτυχθεί από την BASF. Ώς νήμα, το Ultrafuse 316L αποτελείται κατά 80% από ανοξείδωτο ατσάλι ενώ το υπόλοιπο 20% αποτελείται από πολυμερές που του επιτρέπει να εκτυπώνεται εύκολα σε πολλούς επιτραπέζιους 3D εκτυπωτές.

Tα εκτυπωμένα κομμάτια πρέπει να αποσταλούν στην BASF για να γίνει η διαδικασία μετατροπής από το green part στο τελικό sintered μεταλικό αντικείμενο. Απαιτείται κουπόνι για την πληρωμή της υπηρεσίας.

Ακολουθήστε τα guidelines ΕΔΩ

Stainless Steel Metal Filament for your desktop! Designed for ultimate ease of handling on conventional Fused Filament Fabrication 3D printers. Ultrafuse 316L is an innovative filament for the production of 316L-grade steel parts.

Ultrafuse 316L combines greater freedom of design with a low total cost of ownership. 3D-printed parts acquire their final properties, for example in terms of hardness and strength, through a debinding and sintering process developed by BASF, which has emerged as the industry standard. As a filament, Ultrafuse 316 L is 80% stainless steel and has a 20% polymer content which allows for easy printing on many open FFF desktop printers.

Ultrafuse 316L is cost-effective because:

Our filament works with any open FFF printer, which means low investment cost in hardware

We make use of a highly efficient and established post-processing technology used in the Metal Injection Moulding (MIM) industry

As this is a filament, material handling is much safer and very easy. This allows an easy material exchange in comparison to handling with fine metal powders

BASF | Ultrafuse® 316L Metal Infused Filament in 1.75mm

Designed for ultimate ease of handling on conventional Fused Filament Fabrication 3D printers. BASF Ultrafuse® 316L is an innovative filament for the production of 316L-grade steel parts.

Properties

- Produces parts of stainless-steel type 316L

- Easy handling

- Uniform particle distribution enhancing mechanical properties

- OSHA-friendly processing

- High flexibility allows funneling through complex idler pulleys and guide-roller filament transportation systems in any printer

- Compatible with both Bowden and direct drive extruders through the use of a non-slip outer surface

- Shrinkage during sintering requires adjustment during part design

Print Settings

- Nozzle Temperature: 230 – 250°C

- Bed Temperature: 90 – 120°C

- Bed Material: Glass + approved glues* / polyimide tape (*Dimafix® suggested)

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 15 – 50 mm/s

Highlights

Featured applications

Customer one-offs

Due to its high strength and corrosion resistance, Ultrafuse 316L is the ideal choice for manufacturing parts such as jigs, fixtures, tools, and end-use parts.

Replacement parts

Ultrafuse 316L can be used for custom replacement parts. This pipe adapter has an internal static mixer for threaded and tri-clamp connections.

Small batches

Make complex custom geometries. Below demonstrates a study of freeform complex geometry, using true hollow, enclosed features.

Επιπλέον πληροφορίες

| Βάρος | 4 kg |

|---|---|

| Technology | |

| Filament Type | |

| Filament Brand |

Related Products

Taulman Alloy 910 1.75mm

36,90€ ME ΦΠΑFormlabs Flexible Resin

221,96€ ME ΦΠΑColorfabb XT-CF20 Carbon

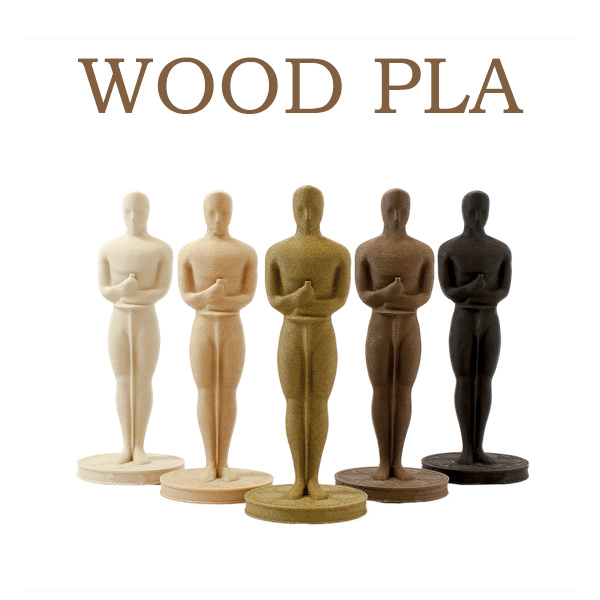

9,90€ – 54,90€ ME ΦΠΑWood PLA 1.75mm

17,90€ – 29,90€ ME ΦΠΑFormlabs Tough Resin

217,00€ ME ΦΠΑAprinta PrintaFix Basic 3D Spray

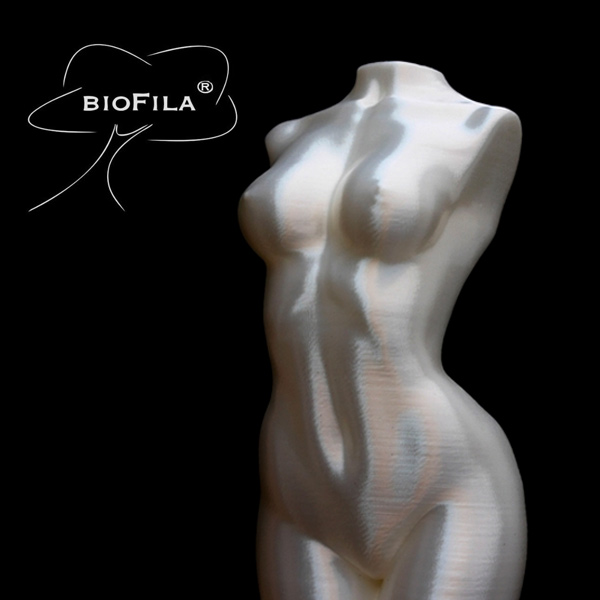

14,90€ – 29,90€ ME ΦΠΑbioFila Silk 1.75mm

9,90€ – 49,90€ ME ΦΠΑ